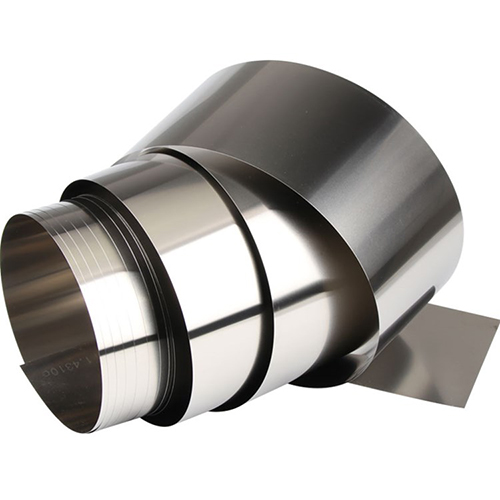

Titin Titanium da Foil

• Titin Tittanium da Kayayyakin Karfe:Titanium (CP) da Titanium alloy foil,Darasi na 1, Darasi na 2, Darasi na 5, Na 5, Na 7 da Na 9

• Forms: tsiri ɗaya, a cikin nada, ko a kan spool.Akwai sabis na tsaga

• Girma:Kauri: ≥0.01mm: 20 ~ 1000mm, Tsawon: Kamar yadda Bukatar

• Sharuɗɗa:Cold rolled(Y)~Zafi birgima(R)~Annealed (M)~ Matsayi mai ƙarfi

• Ka'idoji:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 da dai sauransu

• Aikace-aikace:Kayan lantarki, sinadarai, agogon hannu, tabarau, kayan ado, kayan wasanni, injina, kayan aikin plating, kayan muhalli, golf da ingantattun masana'antu.

| Titanium Alloys Material Name Common | ||

| Gr1 | Saukewa: R50250 | CP-Ti |

| Gr2 | Saukewa: R50400 | CP-Ti |

| Gr4 | Saukewa: R50700 | CP-Ti |

| Gr7 | Saukewa: R52400 | Ti-0.20Pd |

| G9 | Saukewa: R56320 | Ti-3AL-2.5V |

| G11 | Saukewa: R52250 | Ti-0.15Pd |

| G12 | Saukewa: R53400 | Ti-0.3Mo-0.8Ni |

| G16 | Saukewa: R52402 | Ti-0.05Pd |

| G23 | Saukewa: R56407 | Ti-6Al-4V ELI |

Titin Titanium da Foil:Mu yafi samar da tsantsa titanium Strip na Gr1, Gr2, Gr4 maki;Domin titanium gami tsare, Mu yafi samar Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 da sauran maki, An samar a kan tushen da titanium farantin tare da kara sanyi mirgina;tsarin samar da takardar titanium ya fi rikitarwa.Gudanar da nakasawa ya fi tsayi a cikin tsarin juyawa.Wannan za a iya yanke shi a cikin nau'i-nau'i daban-daban bisa ga bukatun abokin ciniki, yana rage girman lokacin bayarwa.

♦ Titanium Strip Chemical abun da ke ciki ♦

| Daraja | Abubuwan sinadaran, kashi dari (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Sauran Abubuwan Max.kowanne | Sauran Abubuwan Max.duka | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy StripKaddarorin jiki ♦

| Daraja | Kaddarorin jiki | |||||||

| Ƙarfin ƙarfi Min | Ƙarfin bayarwaMin (0.2%) | Tsawaitawa a cikin 4D Min (%) | Rage Yanki Min (%) | Lanƙwasa Gwajin (Radius na Mandrel) | ||||

| ksi | MPa | ksi | MPa | 1.8mm A cikin kauri | 1.8-4.8mm A kauri | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

•Darasi na 1: Tsaftataccen Titanium, ƙarancin ƙarfi da ƙarancin ƙarfi.

•Darasi na 2: Tsaftataccen titanium da aka fi amfani dashi.Mafi kyawun haɗin ƙarfi

•Darasi na 3: Babban ƙarfin Titanium, ana amfani da shi don Matrix-plates a cikin harsashi da masu musayar zafi na bututu

•Mataki 5: Mafi ƙera titanium gami.Ƙarfi mai ƙarfi.high zafi juriya.

•Mataki na 7: Mafi girman juriya na lalata a cikin ragewa da muhallin iskar oxygen.

•Mataki na 9: Ƙarfi mai ƙarfi da juriya na lalata.

•Darasi na 12: Kyakkyawan juriya mai zafi fiye da tsantsar Titanium.Aikace-aikace kamar na Grade 7 da Grade 11.

•Mataki na 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy don aikace-aikacen dasa shuki.