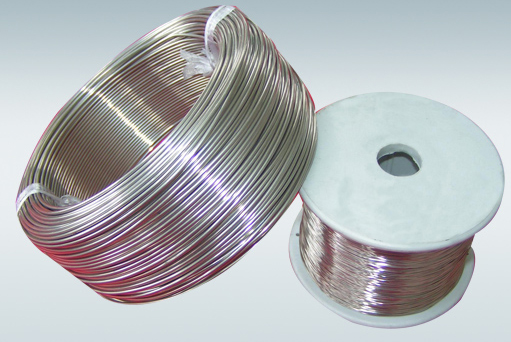

Titanium Wire

Titanium WireAna amfani da waya ta titanium yawanci don waldawa, firam ɗin, gyare-gyaren tiyata, kayan ado, ƙirar rataye ta lantarki.Ana amfani da ita wajen samar da foda mai siffar zobe.

Waya ta yi amfani da sandar titanium ko slab ɗin Titanium tinto ƙirar ƙira don aiwatarwa, saboda tasirin ja, sandar titanium yana lalacewa a ƙarƙashin babban zafin jiki lokacin ta cikin rami na mold.An rage sashin giciye, kuma tsawon ya karu.Ƙaddamarwa a cikin yanayin zafi yana taimakawa wajen kawar da damuwa na ciki da kuma inganta filastik na wayoyi na titanium.Yana inganta daidaitaccen madaidaicin waya na titanium, da ƙarewar saman, wanda zai iya cimma kyakkyawan aiki mai mahimmanci.

• Tittanium Wire Materials: Grade1, Darasi na 2, Darasi na 5, Darasi na 5, Mataki na 7 , Darasi na 9, Darasi na 11, Darasi na 12, Darasi na 16, Grade23 ect

• Siffofin waya: Spool a cikin Coil, Yanke tsayi/Madaidaici

• Diamita0.05mm-8.0mm

• Sharuɗɗa:Magani An warware, Zafafan birgima, Miƙewa

• Sama:Pickling Fari, goge mai haske, Wanke Acid, Baƙar oxide

• Ka'idoji:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 da dai sauransu

| Titanium Alloys Material Name Common | ||

| Gr1 | Saukewa: R50250 | CP-Ti |

| Gr2 | Saukewa: R50400 | CP-Ti |

| Gr4 | Saukewa: R50700 | CP-Ti |

| Gr7 | Saukewa: R52400 | Ti-0.20Pd |

| G9 | Saukewa: R56320 | Ti-3AL-2.5V |

| G11 | Saukewa: R52250 | Ti-0.15Pd |

| G12 | Saukewa: R53400 | Ti-0.3Mo-0.8Ni |

| G16 | Saukewa: R52402 | Ti-0.05Pd |

| G23 | Saukewa: R56407 | Ti-6Al-4V ELI |

♦ Titanium Wire Chemical Composition ♦

| Daraja | Abubuwan sinadaran, kashi dari (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Sauran Abubuwan Max.kowanne | Sauran Abubuwan Max.duka | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy WireAbubuwan Jiki ♦

| Daraja | Kaddarorin jiki | |||||

| Ƙarfin ƙarfi Min | Ƙarfin bayarwa Min (0.2%) | Tsawaitawa a cikin 4D Min (%) | Rage Yanki Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Titanium Alloy Materials Features: ♦♦♦

•Darasi na 1: Tsaftataccen Titanium, ƙarancin ƙarfi da ƙarancin ƙarfi.

•Darasi na 2: Tsaftataccen titanium da aka fi amfani dashi.Mafi kyawun haɗin ƙarfi

•Darasi na 3: Babban ƙarfin Titanium, ana amfani da shi don Matrix-plates a cikin harsashi da masu musayar zafi na bututu

•Mataki 5: Mafi ƙera titanium gami.Ƙarfi mai ƙarfi.high zafi juriya.

•Mataki na 9: Ƙarfi mai ƙarfi da juriya na lalata.

•Darasi na 12: Kyakkyawan juriya mai zafi fiye da tsantsar Titanium.Aikace-aikace kamar na Grade 7 da Grade 11.

•Darasi na 23: Titanium-6Aluminum-4Vanadium don aikace-aikacen dasa shuki.